Description

Quickly. Precisely. Reliable. when assembling cylinders

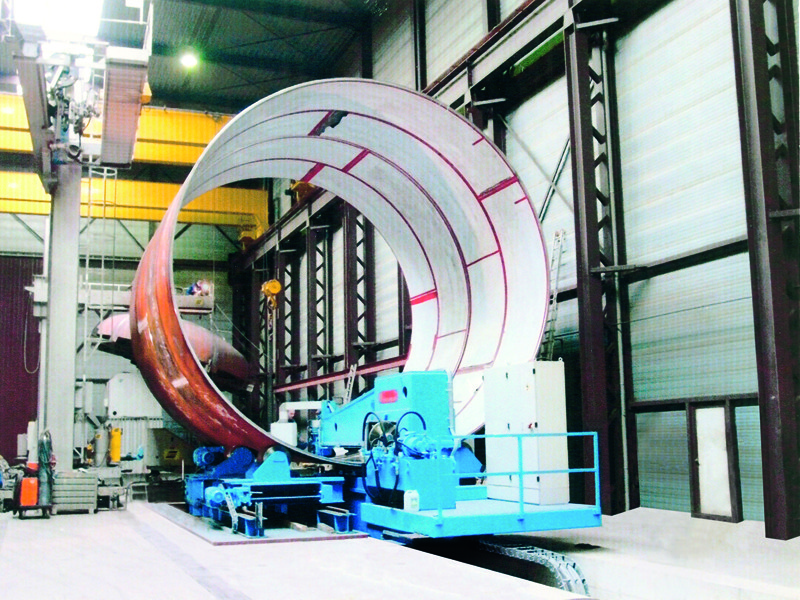

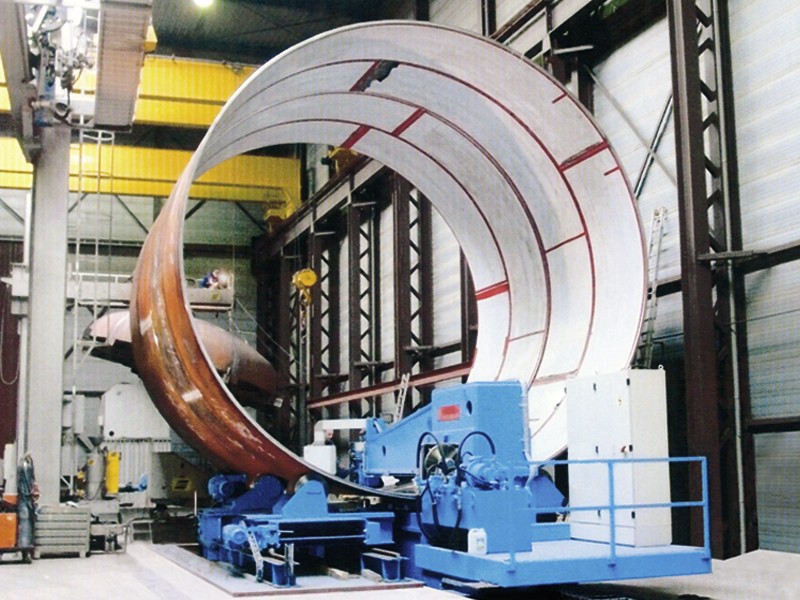

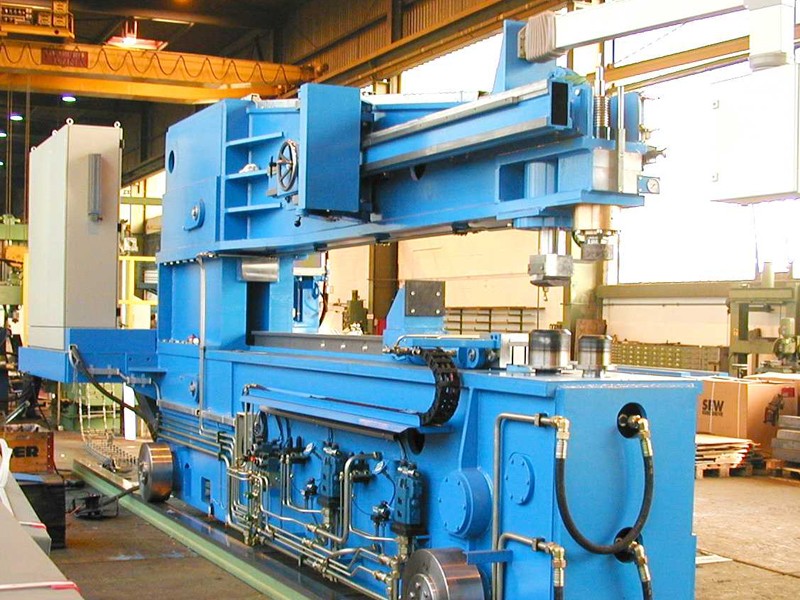

The HAEUSLER Crocodile can be classified as a mobile work centre which, when assembling cylinders, enters one cylinder at a time, positions it correctly with the help of individually adjustable rotating rollers and then welds it over its entire circumference.Due to the very simple positioning and clamping of the cylinders, time savings of up to 85% can be achieved compared to the manual process.

Operating principle

the HAUSLER crocodile

Work sequence when working with the HAEUSLER crocodile

- Loading the rotating rollers with the 1st and 2nd shell

- Retracting the HAEUSLER crocodile between the two shells

- Sliding together shell 2 and shell1 butt-to-end by means of slide

- Longitudinal and radial alignment of the butt joint and manual stapling of the two shells

- Raising the clamping jaws and retracting the HAEUSLER crocodile

- Lifting the section at the rear end from the rotating roller device

- Advancing the section and depositing the rear end of the section centrally on the divided, driven roller block device

- Returning the HAEUSLER crocodile to the rearmost position for loading the next shell

- Load the next shell and start according to step 2 to step 8

Shell diameter

1500 – 12000 mm (crocodile)

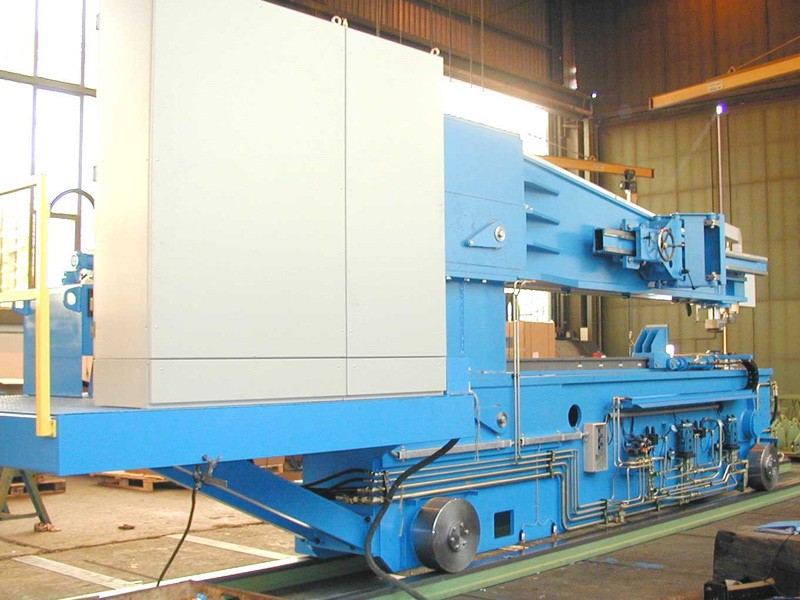

1200 – 5000 mm (clamp)

Wall thickness

12 – 120 mm (crocodile)

4 – 25 mm (clamp)

Metal structure length

Maximum 50m (crocodile)

Maximum 20m (clamp)

Metal structure weight

Maximum 400 tons (crocodile)

Maximum 30 tons (clamp)

-

- Example: serial production of wind turbines

Section I

Assembly of 8 shells- diameters from 2640 to 3117 mm (conical)

- Wall thickness from 12 to 14 mm.

- length of one shell 3 m

- metal structure length 24 m

Total cycle time 2 hours + 50 minutes

Section II

Assembly of 7 shells

- diameters from 3278 to 3669 mm (tapered)

- wall thickness from 14 to 16 mm

- length of one shell 3 м

- length of the finished metal structure 21 m

Total cycle time 2 hours + 45 minutes

Section III

Assembly of 7 shells

- diameters from 3828 to 4219 mm (tapered)

- wall thickness from 16 to 22 mm

- length of one shell 3 м

- length of the finished metal structure 21 m

Total cycle time 3 hours

Section IV

Assembly of 7 shells

- diameters from 4300 mm (cylindrical)

- wall thickness from 22 to 26 mm

- length of one shell 3 м

- length of finished metal structure 15 m

Total cycle time 2 hours + 5 minutes

+998 91 794 22 00

+998 91 794 22 00 info@promex-world.com

info@promex-world.com