Description

Perfectly welded pipes,

from beginning to end

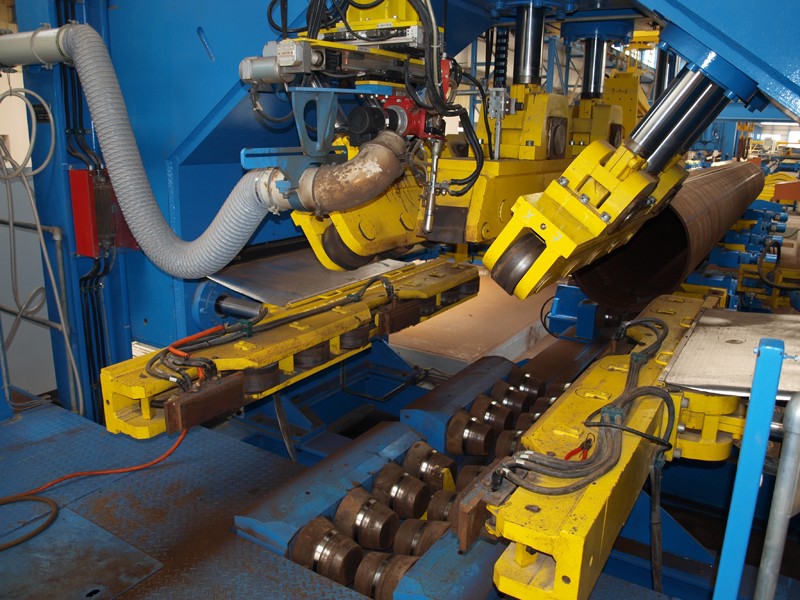

The accuracy of the edge alignment and continuity of the weld bead of the tack welding process is the basis for all subsequent submerged arc welding processes and thus the key factor for pipe quality. The latest generation of HAEUSLER tack welding machines ensures a new level of pipe quality through active pipe manipulation during the welding process (Spinning Control).

This patented system in combination with the high-low rollers installed on the machine, which ensure a perfect weld seam from the beginning to the end of the pipe and the CNC-controlled laser tracking with digital welding equipment, offers the absolute production flexibility and an assured stable production.

- Roll forming

- U-shaped and O-shaped forming

- Sequential stamping process

- Rolling

The CRWM continuous root welding machine can also be used to modernize an existing pipe mill, as it allows:

- improve quality

- increase productivity

The process involves continuous gas-shielded root arc welding to ensure the best quality welds.

CRWM closes the edges of an open pipe seam while it moves on the roll stand.

The roller stand is adjusted hydraulically and using CNC, depending on the pipe parameters, such as diameter, wall thickness, material grade and length.

Nominal pipe diameter

Min. 12″ (304.8 mm)

Max. 64″ (1625.6 mm)

Pipe wall thickness

Min. 0.172″ (4.34 mm)

Max. 1.500″ (38.1 mm)

Pipe length

Min. 20 ft (6096 mm)

Max. 60 ft (18288 mm)

-

-

- Pipeline assembly

+998 91 794 22 00

+998 91 794 22 00 info@promex-world.com

info@promex-world.com